Deerfield and Roundabout Railway

LFLSRM Inc.

New Car Wheel Manufacturing

by J. G. Hook

(Scroll down for all illustrations. Captions above illustrations.)

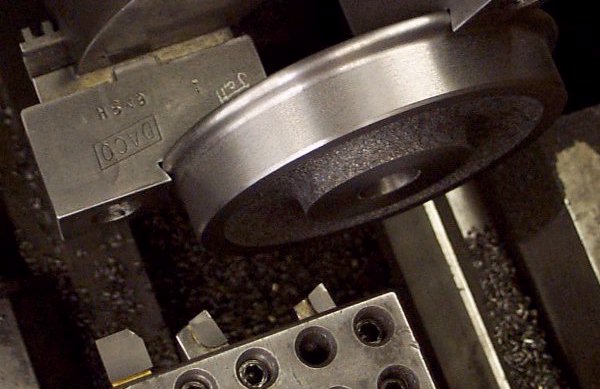

Third operation. Rim chamfering with brazed carbide tool bit mounted on tool holder mounted on lathe compound slide using manual cross feed. Spindle speed 370 rpm., 460 sfpm. After the right tool bit completes facing the front hub, the power cross feed is disengaged and the cross slide is fed manually to machine the rim chamfer with the left tool bit.

Third operation continued. Manual feeding of the cross slide is continued until the cross slide stop is reached. The cross slide stop is adjusted to maintain the required chamfer dimensions for whatever setting the compound slide dial is set for.

Fourth operation. The cross slide is moved approximately 0.100 inches from the work, the carriage is unlocked and moved approximately two inches from the work. The cross slide is then returned to the starting position for the first operation. The lathe is stopped and the completed wheel is removed. Third set up average production rate 55 wheels per hour. Combined average production rate for all operations 6.98 wheels per hour.