Deerfield and Roundabout Railway

LFLSRM Inc.

New Car Wheel Manufacturing

by J. G. Hook

(Scroll down for all illustrations. Captions above illustrations.)

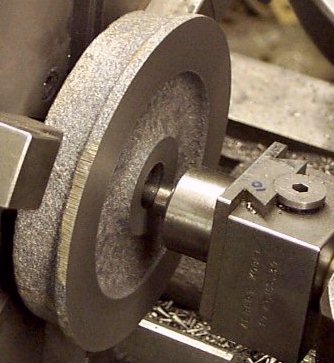

Third operation continued. After the outside tool bit completes facing the back of the flange the power cross feed and carriage lock are disengaged. The carriage is moved to the right and the cross slide is moved to bring the tool post back to the original parking position which clears the tool post and tool bits from the chuck jaws and the ram of the turret.

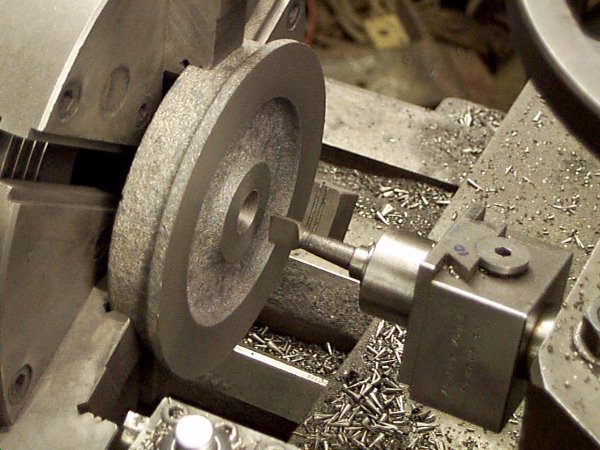

Forth operation. Hole boring with cobalt boring bar mounted in boring head mounted on turret. Spindle speed 370 rpm., 71 sfpm., turret hand feed. The boring operation makes the hole square to the face of the back hub and concentric with the centerline of the lathe. This corrects the typical inaccuracies produced by the twist drill used in producing the hole in the second operation. A conventional vertical milling machine boring head is used to provide a means of regulating the location of the boring bar to compensate for tool wear.

Forth operation continued. The boring operation is performed after the back hub facing operation in order to prevent the boring bar from starting on the rough casting surface.

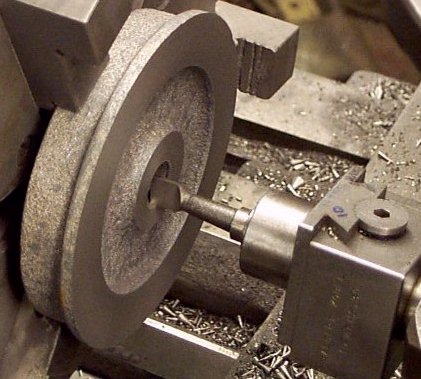

Forth operation continued. Boring bar at the end of the cut. After completion of the boring operation the boring bar is withdrawn and the turret is indexed from the boring bar to the reamer.