Deerfield and Roundabout Railway

LFLSRM Inc.

New Car Wheel Manufacturing

by J. G. Hook

(Scroll down for all illustrations. Captions above illustrations.)

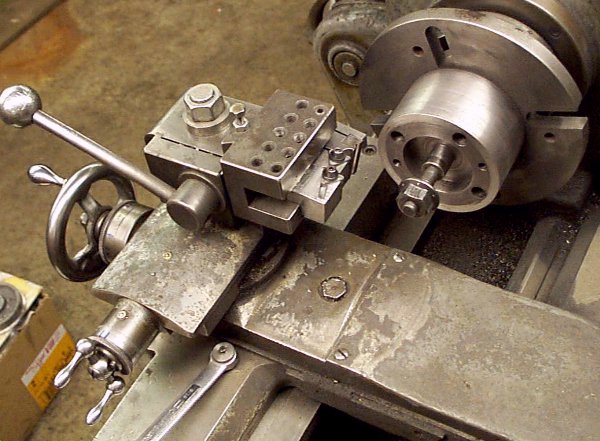

Second set up for turning operations to produce D&R Cylindrical Wheel Tread and Flange Contour having 4.500 inch diameter wheel tread, 3/32 inch flange throat radius, 5/32 inch flange width, 80 degree outside flange angle, 3/16 inch flange height and 3/32 inch flange radius on 13 inch "Sheldon" gear head lathe equipped with cross slide quick change tool post, multiple tool bit holder and wheel tread and flange turning fixture. Second set up average production rate 16 wheels per hour.

First operation. Mounting wheel blank machined in the first set up on the turning fixture and starting lathe.

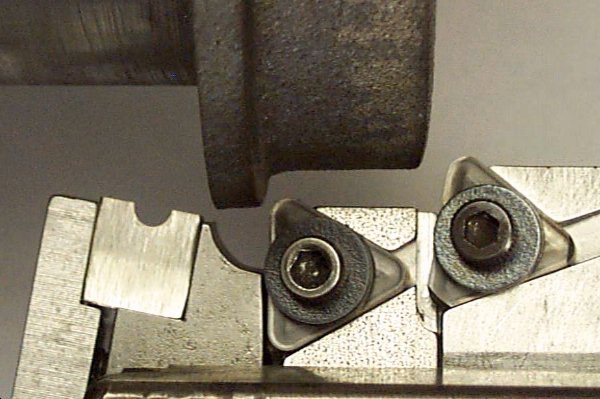

Second operation. Machining of first rough flange diameter of 4.920 inches, rough tread diameter of 4.520 inches and finished flange width of 0.156 inches. The compound slide dial is set to reference "CP-A," the carriage is positioned for starting the cut, the cross slide dial is set to reference "CS-A" and the power carriage feed is engaged.

Below is an illustration of a typical machining chart that the turret lathe operator refers to when setting the cross slide and compound slide dials for the various operations.

Second operation continued. The left carbide insert cuts the first rough flange diameter. The right carbide insert cuts the rough tread diameter. Spindle speed 150 rpm., 197 sfpm., lathe power carriage feed rate 0.008 ipr.