Deerfield and Roundabout Railway

LFLSRM Inc.

New Car Wheel Manufacturing

by J. G. Hook

(Scroll down for all illustrations. Captions above illustrations.)

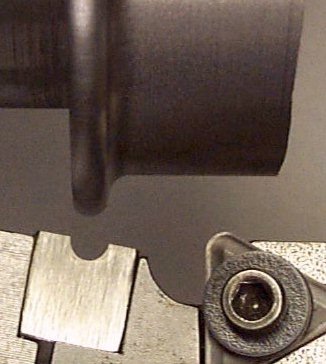

Third operation continued. When the right carbide insert nears the flange throat radius the power feed is disengaged and the carriage is fed manually to continue cutting the finished tread diameter. Manual feed rate is approximately 0.004 ipr. After the carriage reaches the left side carriage stop, it is held there until the carbide insert no longer produces any chips.

Third operation continued. The cross slide is moved to bring the tool bits away from the work. The carriage is then moved to the right side carriage stop.

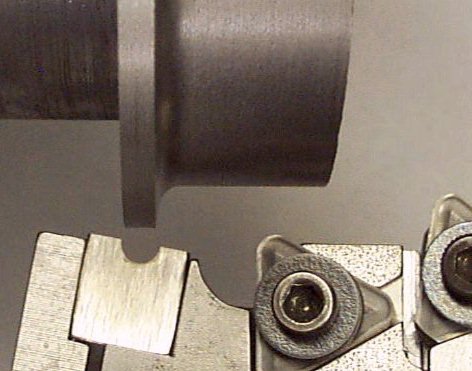

Forth operation. Machining of 0.094 inch flange radius and finished flange height of 0.188 inches. The carriage is locked against the right side carriage stop which is adjusted to bring the flange radius form tool into proper location with the compound slide dial setting remaining at reference "CP-B." The cross slide is manually fed into the work and is stopped when the cross slide dial reading reaches reference "CS-C."

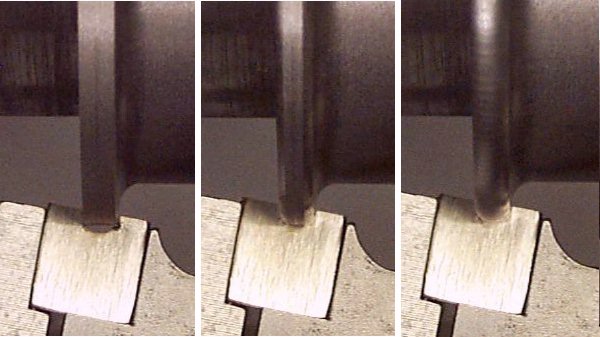

Forth operation continued. Three views showing the radius form tool at the beginning, middle and end of the cut. Spindle speed 100 rpm., 131 sfpm., manual cross slide feed rate approximately 0.004 ipr. The cross slide dial reference "CS-C" is adjusted in order to compensate for tool wear.

Fifth operation. After the flange radius has been machined, the cross slide is moved to clear the tools from the work, the lathe is stopped and the wheel is removed from the turning fixture.